Choosing the Right Industrial IoT Solution for Your Business — Powered by Merjio AI

From rugged edge devices and resilient connectivity to centralized device management, cloud APIs, real-time dashboards, and end-to-end edge-to-cloud platforms, Industrial IoT (IIoT) solutions now cover every step of the data journey—from shop-floor assets to enterprise systems.

But data alone isn’t enough. AI turns raw signals into operational intelligence—detecting anomalies early, predicting failures, explaining performance shifts, and recommending actions in real time.

In a crowded IIoT marketplace, Merjio brings IoT and AI together in one unified platform—simplifying integration, scaling across sites and assets, and keeping data protected end-to-end. When evaluating any IIoT platform, prioritize the three essentials Merjio is built around: Simplicity, Scalability, and Security.

Features

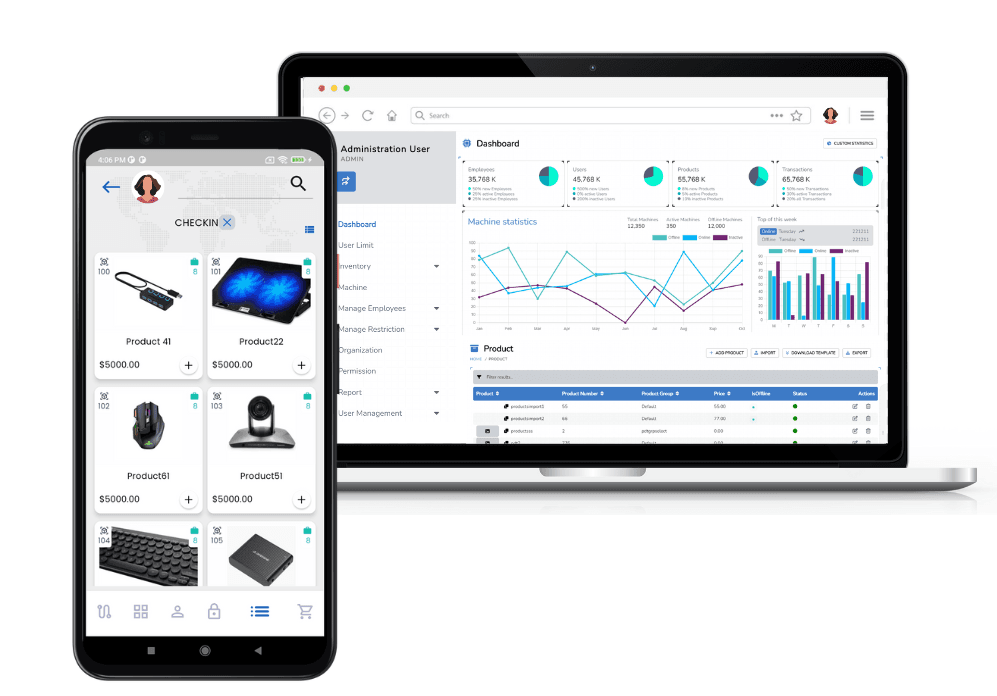

Real-time data analysis for proactive decision-making and operational optimization.

Streamlined asset and inventory management for efficient tracking and optimization of resources.

Centralized device management for enhanced control and scalability of IoT devices.

Integrated reporting for comprehensive insights into operational performance and areas for improvement.

Secure cloud-based infrastructure for seamless data storage, scalability, and accessibility.

Predictive maintenance (IIoT + AI) : Move from scheduled preventive maintenance to AI-driven predictive maintenance

Unlock strategic customer insights and actionable intelligence from product-usage data using AI-driven analytics

Anomaly Detection: Real-time anomaly detection identifies unusual patterns in building operations, alerting facility managers to potential issues instantly. The AI distinguishes between normal variations and critical problems requiring attention.

How IIoT + AI Solutions Are Accelerating Industry 5.0

Industry 5.0 is no longer just a buzzword—it’s already taking shape. In an era defined by disruption, rising energy costs, and supply-chain volatility, industrial companies are adopting Industrial IoT (IIoT) and AI not only to digitize operations, but to build a future that is human-centric, sustainable, and resilient.

By unlocking trusted, real-time data from industrial assets, organizations can enable remote asset monitoring, real-time performance visibility, predictive maintenance, and smart asset tracking—while also improving worker safety, reducing waste, and strengthening continuity across plants and sites.

These capabilities help companies cut costs, differentiate products and services, and evolve business models—while aligning operations with Industry 5.0 outcomes. IIoT-enabled data is enabling companies to:

Protect people and improve well-being with safer operations, alerts, and assistive workflows

Increase resilience through early-warning systems, predictive maintenance, and faster recovery from disruptions

Drive sustainability by optimizing energy, reducing scrap, minimizing emissions, and improving resource efficiency

Enable human–machine collaboration with AI guidance, contextual insights, and decision support—not just automation

Improve traceability and compliance with end-to-end visibility across assets, processes, and quality events

Deliver smarter services (e.g., uptime-based models, remote diagnostics, and outcome-driven SLAs)

Streamline Asset and Inventory Management with our IoT-Based Platform

Overcome IoT Data Management Challenges in Manufacturing