Product Manufacturing Process: Key Factors to Consider

Product Manufacturing Process: A Step-by-Step Guide

Bringing a product from concept to reality involves a crucial stage known as manufacturing preparation. This pivotal step ensures that your product is ready for mass production and meets the required quality standards. However, this process can be complex and challenging without careful planning and consideration of various factors. In this blog post, we will explore the key aspects you need to take into account when making your product ready for manufacturing. By addressing these considerations, you can streamline the manufacturing process, minimize setbacks, and maximize the chances of a successful product launch.

1. Design for Manufacturing (DFM)

Design for Manufacturing (DFM) is a critical aspect of preparing your product for mass production. It involves optimizing the design to ensure efficient and cost-effective manufacturing processes. By considering manufacturing constraints during the design phase, you can avoid potential issues and reduce production costs.

Collaboration between the design and manufacturing teams is crucial. Effective communication and cooperation between these teams ensure that the design aligns with the manufacturing capabilities and limitations. Regular meetings and feedback loops help identify areas for improvement and resolve any conflicts that may arise.

Design simplification and optimization are key to enhancing manufacturability. Simplifying complex features, minimizing the number of components, and optimizing part geometry can lead to reduced production time and costs. Additionally, standardized components and materials facilitate smoother manufacturing processes and better economies of scale.

2. Prototyping and Testing

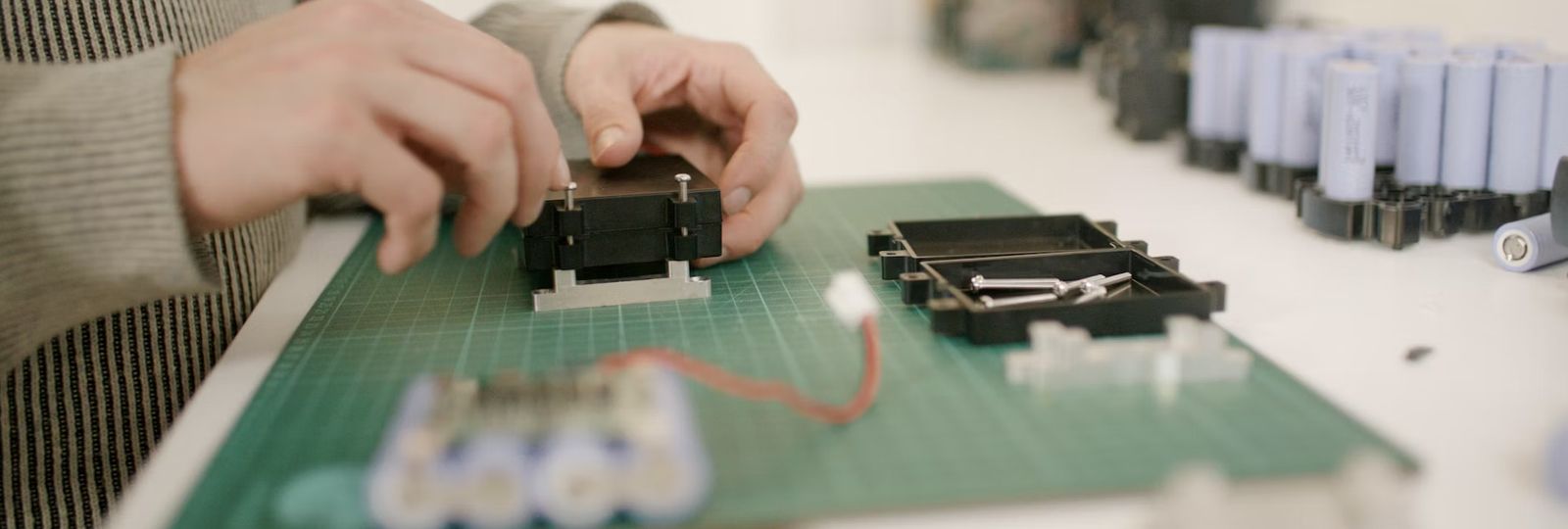

Prototyping and testing are essential steps to ensure that your product functions as intended and meets quality requirements before mass production. Prototyping allows you to identify and rectify design flaws, assess product reliability, and optimize performance.

Prototyping typically involves multiple stages, starting with initial concepts and progressing to more refined prototypes. Through iterative refinement and testing, you can gather feedback, make necessary improvements, and validate the product's functionality and usability.

By identifying design flaws early on, you can save significant costs and time that would otherwise be incurred during the mass production stage. Prototyping also enables you to refine the manufacturing process and establish reliable quality control measures.

3. Materials and Suppliers

Selecting the right materials for your product is crucial for both functionality and manufacturing efficiency. Consider the specific requirements of your product, such as strength, durability, and environmental compatibility, when choosing materials.

Evaluate material properties and availability to ensure that your chosen materials can be sourced consistently and meet the necessary quality standards. Conduct thorough research and testing to understand how different materials perform in your product's intended application.

Supplier qualification is another critical factor. Identify reliable and reputable suppliers who can consistently provide high-quality materials. Establish strong relationships with your suppliers to ensure timely deliveries, negotiate favorable terms, and address any potential supply chain disruptions.

4. Manufacturing Process Selection

Understanding different manufacturing processes is vital in selecting the most suitable one for your product. Consider factors such as product complexity, desired production volume, cost, scalability, and quality requirements.

Some common manufacturing processes include injection molding, machining, casting, and additive manufacturing. Each process has its own strengths and limitations. Choose a process that aligns with your product's design, budget, and time constraints.

Additionally, assess production volume and lead time requirements. If you anticipate high demand, processes with shorter lead times and higher scalability may be more appropriate. Conversely, for low-volume or specialized products, processes that offer more flexibility and customization might be preferred.

5. Tooling and Equipment

Developing the necessary tooling, such as molds, dies, and fixtures, is essential for efficient manufacturing. Collaborate with tooling experts who can design and produce high-quality tools tailored to your product's specifications.

Assess your equipment needs and capabilities to ensure they align with the manufacturing process you've chosen. Acquire reliable machinery that can handle the production volume and meet quality requirements. Regular maintenance and calibration of equipment are essential to minimize downtime and ensure consistent production.

Compatibility between tooling, equipment, and manufacturing processes is crucial. Ensure that your tooling is compatible with the chosen manufacturing process and that your equipment can accommodate the required tooling.

6. Quality Control and Testing

Implementing robust quality control measures is vital to ensure consistent product quality during manufacturing. Define product specifications and standards, and establish inspection and testing protocols to verify adherence to these requirements.

Conduct inspections and tests at various stages of production to detect any non-conformances early. This allows for timely corrective actions and prevents the production of defective or substandard products. Regular audits and process evaluations help identify areas for improvement and maintain quality standards.

Address non-conformances promptly to prevent the accumulation of faulty products and minimize the risk of product recalls or customer dissatisfaction. Continuous monitoring and analysis of quality data can help identify trends and implement proactive measures to improve overall product quality.

FAQs

What is Design for Manufacturing (DFM)?

Design for Manufacturing (DFM) is a design approach that considers manufacturing constraints and requirements from the early stages of product development. It focuses on optimizing the design to enhance manufacturability, reduce costs, and improve efficiency during mass production.

Why is prototyping essential before manufacturing a product?

Prototyping allows you to test and refine your product's design, functionality, and performance before mass production. It helps identify design flaws, evaluate reliability, and make necessary improvements, saving time and costs in the long run.

How can I select the right manufacturing process for my product?

To select the appropriate manufacturing process, consider factors such as product complexity, production volume, cost, scalability, and quality requirements. Evaluate different processes, their advantages, and limitations, and choose the one that aligns with your product's needs and goals.

What are some key aspects of quality control during manufacturing?

Key aspects of quality control during manufacturing include defining product specifications, conducting inspections and tests at various stages, addressing non-conformances promptly, and continuously monitoring and analyzing quality data to drive improvements.

How important is regulatory compliance for product manufacturing?

Regulatory compliance ensures that your product meets safety, environmental, and quality standards set by relevant regulatory bodies. Compliance is essential to protect consumers, avoid legal issues, and maintain a positive brand reputation.

What strategies can I employ to optimize manufacturing costs?

To optimize manufacturing costs, consider factors such as material selection, process efficiency, supply chain optimization, and waste reduction. Streamlining processes, negotiating favorable terms with suppliers, and implementing continuous improvement initiatives can also help reduce costs.

How does supply chain management impact product manufacturing?

Effective supply chain management ensures a reliable flow of materials, components, and resources required for manufacturing. It minimizes risks, optimizes inventory, ensures timely deliveries, and fosters strong supplier relationships, ultimately impacting the overall efficiency and success of the manufacturing process.

Conclusion

Preparing your product for manufacturing is a critical phase that requires careful attention to numerous factors. By considering the aspects outlined in this blog post, such as design for manufacturing, prototyping and testing, materials and suppliers, manufacturing process selection, tooling and equipment, quality control and testing, regulatory compliance, supply chain management, and cost optimization, you can enhance your product's manufacturability, reduce costs, and improve overall quality. Collaborating closely with design, manufacturing, and supply chain teams, as well as conducting thorough prototyping and testing, will help you identify and resolve potential issues early on.

Additionally, ensuring compliance with regulatory requirements and optimizing the supply chain and manufacturing processes are vital for a successful product launch. Remember, thoughtful preparation and meticulous execution are the keys to a smooth and efficient transition from product development to mass production.